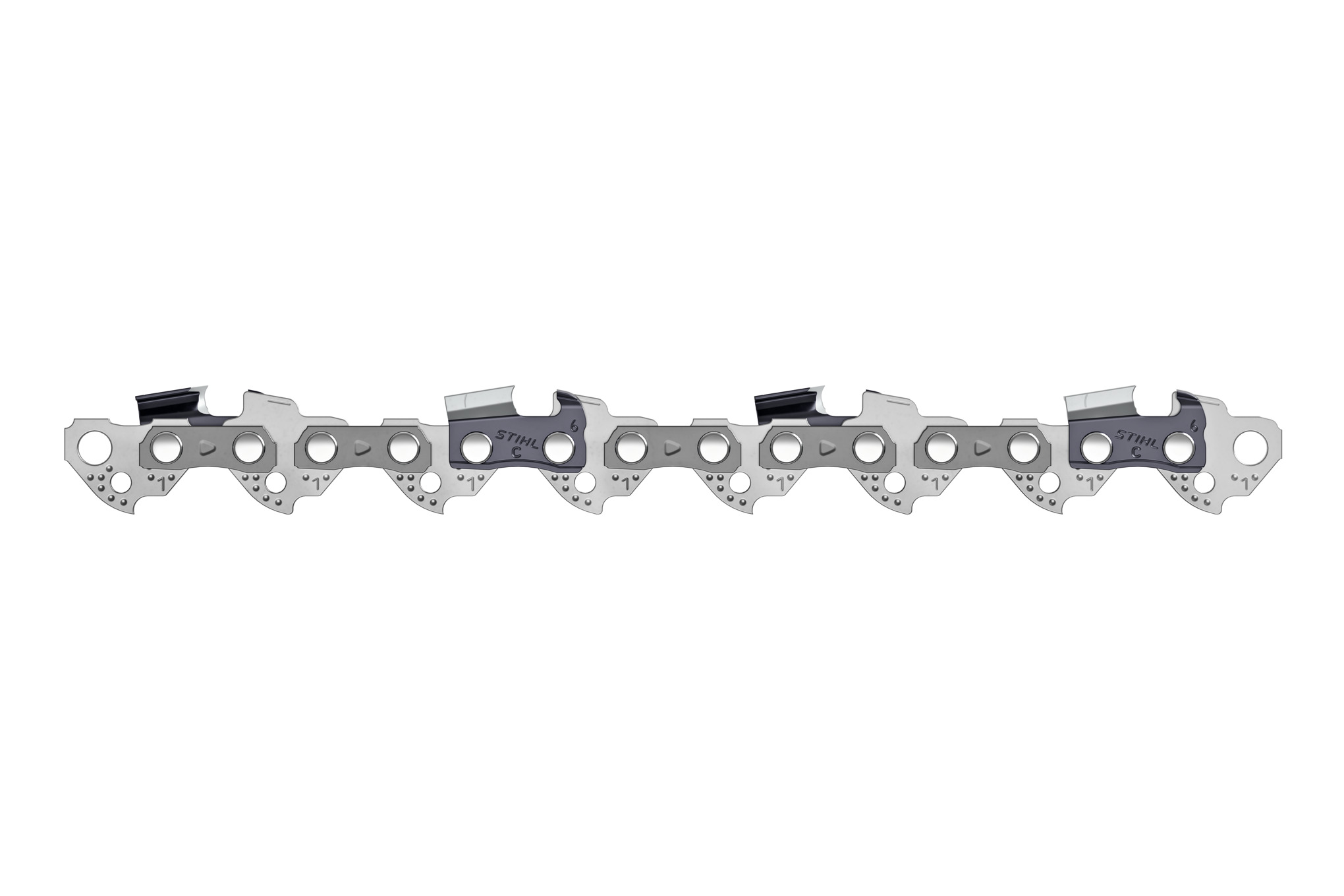

STIHL chainsaw chains and guide bars

All STIHL chainsaw chains and guide bars are developed and tested in-house. This means we can guarantee that the cutting attachment and powerhead are always perfectly tuned to each other – ensuring the best possible performance while you work.

14.11.2025

STIHL chains and guide bars: the perfect combination

When you’re working in the great outdoors, you need equipment that can handle the toughest challenge. That is why we have developed a whole range of chainsaw chains and guide bars to meet a wide variety of requirements. All of our products showcase outstanding technical innovation and high production quality, and when you pair a STIHL guide bar with a STIHL saw chain you will fully benefit from the specialist expertise that goes into what we do.

STIHL saw chains: precision on delivery

For decades, chain has been produced at our factory in the Swiss town of Wil, using specialised machines that were developed in-house. This level of focus on the product makes all the difference, and today STIHL offers saw chains in every performance class and for every brand of chainsaw. You can be assured that STIHL saw chains deliver outstanding cutting performance and a long service life. What are some of thw features that contribute towards this?

This lubrication system ensures less friction and wear on your STIHL saw chain and a longer life for the cutting attachment. Each chain drive link is engineered with a reservoir that picks up chain oil from the guide bar; this oil is then fed to fine channels in the links to lubricate the chain joints and the running surfaces of the chain links, thereby ensuring a consistent lubricating film between the drive links and the gliding surfaces of the guide bar.

Every blade tooth is carefully produced using special steel, and goes through multiple production cycles. In order to increase the wear resistance of the teeth on your chain, the cutter top plate is also galvanised.

The final production step for every STIHL saw chain involves exposure to a high and constant tensile load in order to pre-stretch the chain, which increases durability, reduces wear and minimises the initial stretching that can be expected of a new chain. This in turn considerably reduces the maintenance effort required.

Virtually all STIHL chainsaw chains are comfort saw chains, which can be identified by the letter “C” engraved on the blade tooth. Saw chains with this marking have a specially shaped chain sprocket that reduces vibrations during sawing by up to 70%.

STIHL saw chains have engraved markings on the blade teeth to help you gauge wear and also serve as an aid during sharpening, as they indicate how far it is possible to file the tooth down to when sharpening.

Every rivet is induction-hardened in a strong high-frequency magnetic field. This ensures a particularly robust chain.

A special stamping technique is used to provide the joint borings in STIHL saw chains with a mirror-smooth finish. This improves the running properties of the chain and increases its service life.

All of these features ensure that STIHL saw chains, in combination with guide bars developed by STIHL offer optimal cutting characteristics. STIHL saw chains can also be used with chainsaws from other manufacturers.

Our innovative .325” Pro saw chains include all of the advanced features outlined above, as well as offering 20% improved cutting performance compared to previous .325" chains. This is acheived by reducing the size of the top plate saw kerf.

STIHL guide bars: light, robust, innovative.

The guide bar is responsible for the precise manoeuvring of the saw chain with minimal friction loss, and has to stand up to the toughest strains. STIHL offers perfect guide bars for every area of application, all developed and produced in-house. Decades of research, high-quality materials, innovative production processes and ultra-modern production facilities ensure STIHL quality in every guide bar, as do our electronic production checks and the final quality control stage. This is how every STIHL guide bar proves itself in the face of the challenges it faces every day at work.

The STIHL Ematic system reduces chain oil consumption by up to 50%, depending on the type of wood and the cutting attachment used. The system comprises an Ematic guide bar, an Oilomatic saw chain and a variable-flow or reduced-flow oil pump. With these elements in place, virtually every drop of chain lubricant is delivered to precisely where it’s needed.

Hardening by means of electromagnetic induction ensures that the entire chain rail is even more resistant to every kind of wear. This significantly increases the service life of the guide bar.

Our Rollomatic guide bars have a sprocket nose with covered roller bearings. This means low wear during saw chain operation and also keeps out dirt that can cause corrosion. The closed bearings in the sprocket nose are also lubricated for life, meaning longer durability and less maintenance – helping you save time and protect the environment, as well as reducing the strain on your wallet.

Thanks to their fully symmetrical shape, STIHL guide bars are reversible, making it possible to ensure that both of the long sides wear evenly.

STIHL offers a range of guide bars with a special design that makes them particularly light, distinguished by the word “Light” in the product name. Rollomatic E Light guide bars are made from electrically welded steel plates, which are extensively hollowed out and filled with fibreglass-reinforced polyamide; while Rollomatic ES Light bars are produced by first cutting out the spaces and then being welded together using a special laser process. These processes result in a significant weight saving compared to conventional bars.

Rollomatic E, Rollomatic ES and Duromatic: STIHL guide bars for all applications

STIHL guide bars can be divided into three basic types. Each is designed with different requirements and areas of application in mind, from all-rounder models to professional products. We have listed the key features of our guide bars below for you.

Rollomatic E

- Guide bar for universal use, in a range of designs

- Three metal plates welded together

- Middle plate extensively hollowed out for lightweight design with high stability

- For applications ranging from use in cordless chainsaws to petrol chainsaws with an output of up to 3.5 kW

- Available in bar lengths of 25 cm to 63 cm

Rollomatic ES

- Sturdy solid body with fully replaceable bar nose; includes sprocket nose

- For professional chainsaws with outputs of over 3.5 kW

- Available in bar lengths up to 150cm

Duromatic

- Steel solid body

- Carbide plating on bar nose

- For use with chainsaws in the middle and high performance categories

Summary: STIHL saw chains and guide bars

- All STIHL saw chains and guide bars are developed in-house by STIHL

- The STIHL saw chain range includes products to suit any application

- STIHL saw chains can also be used in chainsaws from other manufacturers

- STIHL guide bars can be divided into Rollomatic E, Rollomatic ES and Duromatic types

- STIHL has the perfect guide bar for every challenge