Development and testing of STIHL batteries

We put our STIHL batteries through extensive testing to ensure outstanding quality and performance – the key test procedures are outlined below.

04.11.2025

Overview: Development and tests

- STIHL batteries and chargers (like the STIHL AP 500 S battery) are put through demanding load tests

- Temperature tests make sure the system functions at low and high temperatures

- Safety tests are conducted in real-world environments, such as professional job sites, to ensure safety in various situations

- Mechanical tests such as the drum test are used to identify potential for optimisation

Testing in practice at STIHL

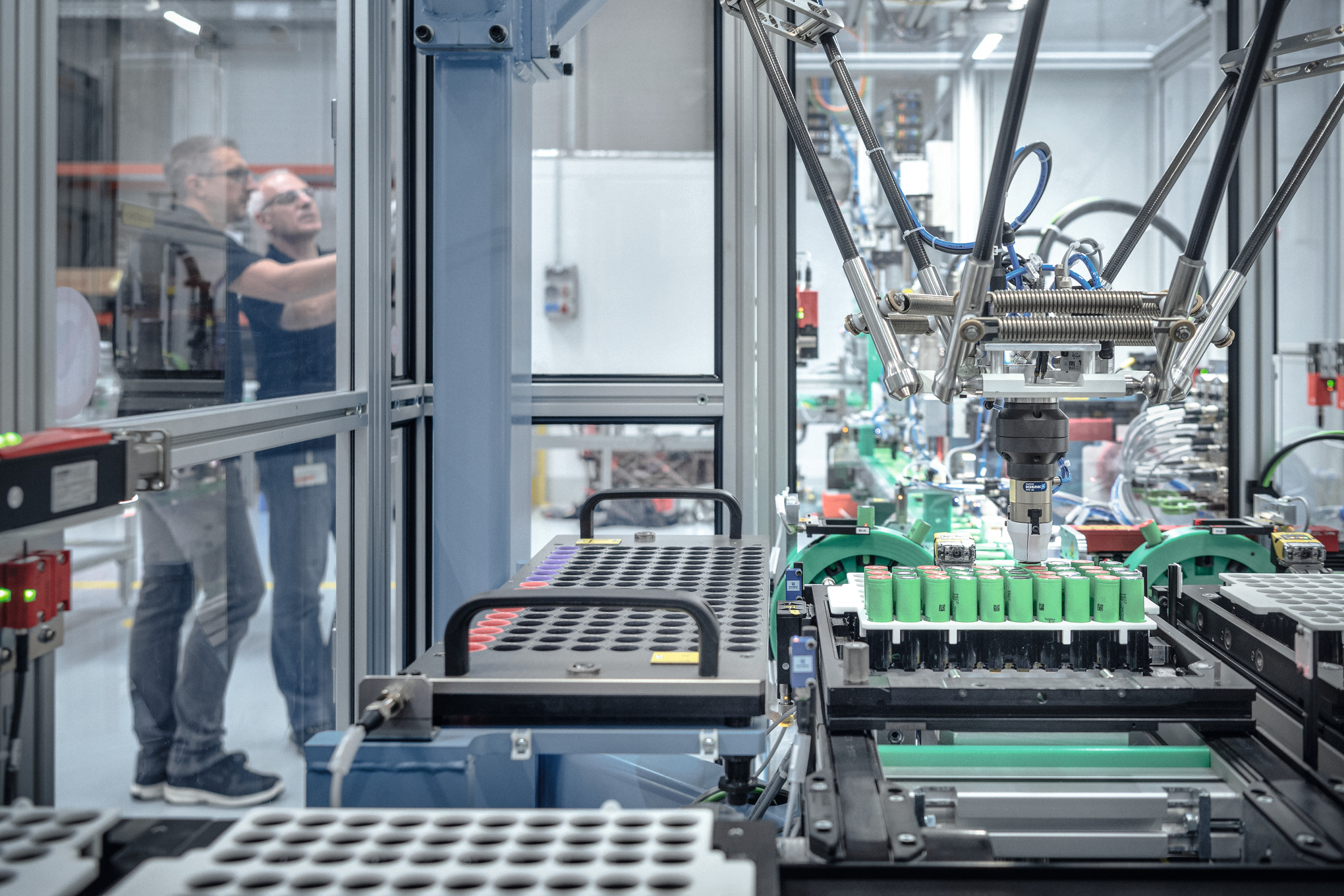

STIHL manufactures high-performance battery products for professionals in Waiblingen, Germany. This includes the AR 2000 L and AR 3000 L backpack batteries, and the STIHL AP 500 S which uses power laminate technology to deliver long runtimes and first-class performance.

The aim of STIHL development is to make sure that all components are optimised to work harmoniously together to provide the greatest possible performance. The batteries are put through their paces in every development phase to ensure that this theory tranlsates into practice.

Examples of tests

Various tests are carried out to make sure our batteries are of the highest quality and meet the needs of professionals in forestry, landscaping and construction. The key test procedures are listed below.

The device is cooled down for the temperature test

Temperature tests

In temperature tests, the device is cooled down to its minimum operating temperature, which could be as low as -20 °C, to make sure the system is ready to start and operate even at low temperatures.

This guarantees reliable performance for professionals working in harsh weather conditions.

A tree trunk is sawn for testing in the application

Safety tests

Safety is a top priority when developing STIHL batteries and chargers. In many cases, we set higher safety requirements than the industry standard or legal requirements.

To this end, we follow systematic methods for fault detection and prevention and extensive safety tests.

The drum test is one of the mechanical tests

Mechanical tests

The drum test simulates a harsh daily working routine by exposing the battery to knocks, blows and vibrations in a rotating drum.

This identifies mechanical optimisation potentials in the structure and design.

Outlook for battery development

Our focus for future development is to offer even more options for increased performance and fast charging processes, to simplify professional work.

Simply powerful: STIHL batteries for professionals

Important questions and answers

Temperature tests, safety tests and mechanical tests are carried out, among other things, to thoroughly test the battery packs and chargers and to ensure the high product quality and safety.

In a temperature test, a device is cooled down to the minimum operating temperature using a temperature test bench to ensure that it is ready to start and operate even in extreme cold.

During a drum test, the battery pack is subjected to knocks, blows and vibrations in a rotating drum device in order to detect possible mechanical optimisation potentials at an early stage.

This ensures the necessary mechanical robustness for professional use of the battery packs.

STIHL battery systems for professionals

Find out which battery power tools and charging solutions suit your activities and your business. Discover high-performance, professional STIHL battery-powered tools now.